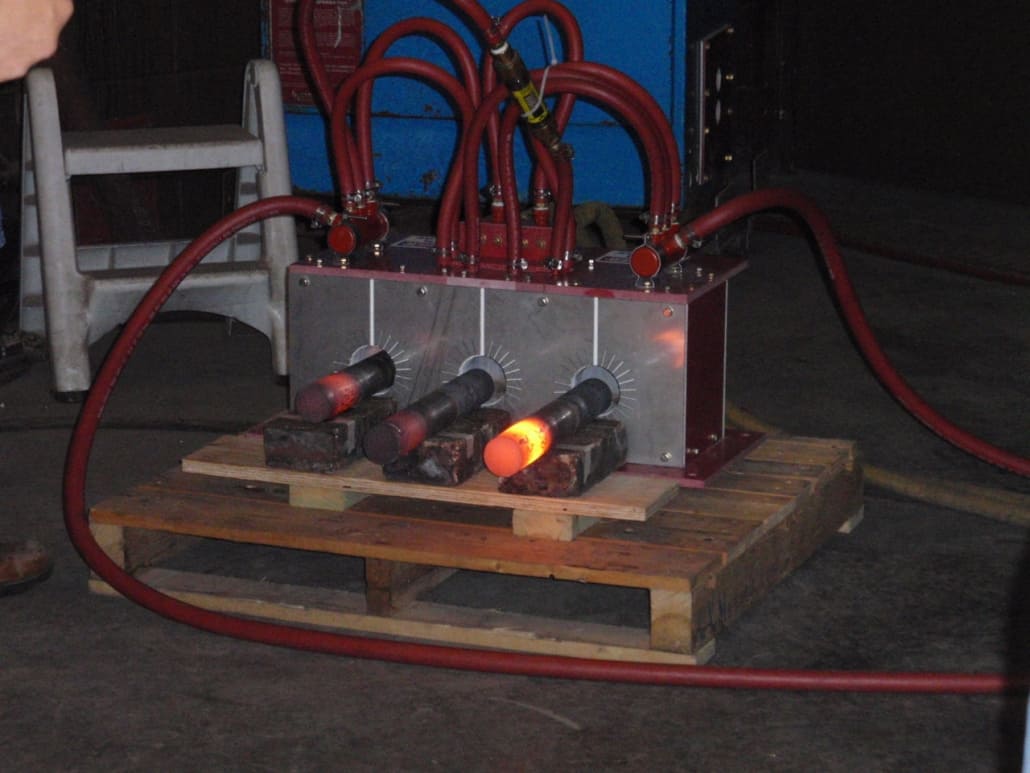

Induction forging is a quick and energy-efficient process used to heat materials using induction heating prior to forming them to your desired shape. Whether it be billet, bar, slab, or other, the induction forging processes delivers superior productivity, part quality, equipment reliability, and work cell flexibility.

Your productivity is improved due to rapid heating, instant startup, optional hold features, ease of integration into an existing process, reduced down-time, reduction of parts in process, and by the fact that the machine can control production rate, not the operator. Induction forging can dramatically improve the consistency of part quality, with significantly reduced scale. With this reduced scale comes substantial decreases in steel (or other metals) consumption and increased die life. The strong reliability factor of induction heating systems is a major advantage, as is the flexibility to often fit within existing work cells.