Induction Heat Treating Technology

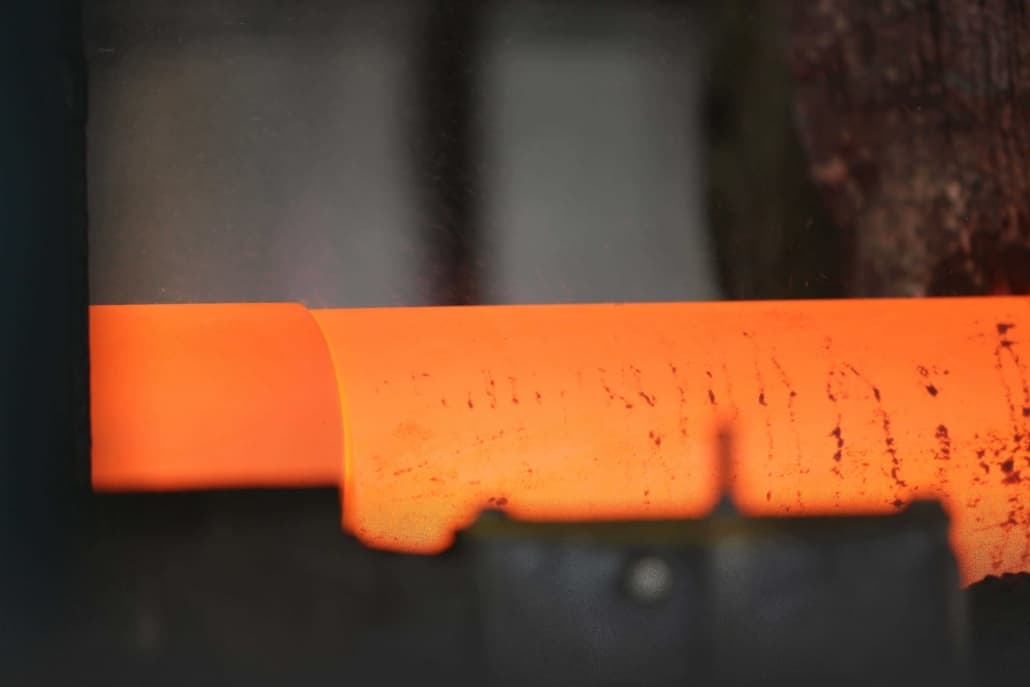

Are you looking to boost the efficiency of your manufacturing process? Induction heating is the most controllable and energy-efficient way to apply heat during the heat treating process. Because the technique is non-contact by nature, our induction heat treating equipment allows for high production rates that meet the most demanding metallurgical requirements. Localized heating and direct magnetic coupling into the part minimizes ambient heat in the local environment, which enhances operator safety and comfort.

Whether you need to harden, soften, or temper your metal components, induction heat-treating equipment is the go-to choice for achieving optimal results.

Why Power Parts?

By incorporating Power Parts induction equipment into your manufacturing setup, you can reduce production time, minimize material waste, and improve overall product quality. The precise control offered by induction heat treating equipment allows for targeted heating, leading to enhanced precision and repeatability in your manufacturing processes.

Don’t let outdated methods hold back your manufacturing efficiency. Talk to Power Parts today about your induction heating needs and let us develop an equipment solution for you to experience the benefits of improved productivity, cost savings, and superior product quality.

Our Induction Heat Treating Equipment & Systems

Our versatile and high-performing induction heat treatment equipment is designed to heat treat your parts using either scanning or single-shot heat treatment induction heating methods. As a leading supplier and innovator of induction equipment, heating equipment systems, heating solutions, and power supplies, Power Parts has the experience, know-how, and products necessary to meet your critical production needs. Put our heating industry experts to work for you! We will meet with you to learn more about your production needs, and will then design and build a high-quality, fully automated induction heating solution within your budget that maximizes your output and remains energy efficient.